Etching and Surface Treatment Machines Incorporating PC Board Manufacturing Know-How

We have had our own printed circuit board (PCB) manufacturing plant since 1953. Putting our board manufacturing know-how into practice, we shifted to a development-oriented company in 1996, and since then we have been engaged in R&D as the front-runner in the electronics industry. In 2005, we launched a “Special Machinery Department,” setting up systems that took our proprietary technologies and process technologies to an even higher stage of evolution.

As a manufacturer of FPC, TAB, and other surface treatment machines, the “Special Machinery Department” has been involved in designing and manufacturing equipment in-house, while tackling the research and development of new technologies that will be able to meet customers’ needs. We will continue to offer not only existing surface treatment machines but also technologies and services that satisfy to the maximum extent a wide range of needs such as applications in new product development and industrial fields.

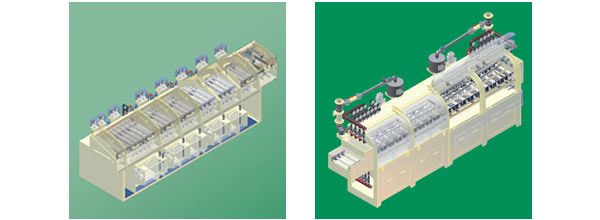

Maintenance-Oriented 3D Design

Machines are designed in 3D to minimize the differences between completed images and those on drawings, and to prepare illustrations that make parts drawings and user instructions easier to understand. Machines are produced one at a time as ordered by the customer and design work moves ahead taking into account maintenance factors such as ease of use and installation conditions of the completed unit. The preparation of detailed drawings right from the design stage results in more accurate data control after manufacturing is completed and ensures that products will be used with confidence for a long time.

Upgrading of Specifications for Existing Machines and Follow-Up

Inspecting your existing machines, we will reduce the percentage defective in production, optimize your running cost, or improve the equipment operating conditions. Our machine design and electric control experts will offer you the best advice.

Description of Business

- Surface treatment machines

- ・Developer, etching machine, stripping machine

・Acid washing machine, brushing machine (brush)

・Brushing machine (chemical)

・Plating machine (FPC, TAB, COF, BGA)

・Washing machine (using pure water)

・Surface treatment machine for semiconductor wafers - Automatic labor-saving machines and general machines

- ・Automatic base veneer feeder/receiver

・Base veneer aggregated feeder/receiver

・Long base material roll-out/roll-in machine

・Fast-feed conveyer, U-turn conveyer

・Automatic chemical solution management machines and systems - Manufacture machines

- ・Conveyer-type dryer, reflow furnace

・Box-type dryer, cleaning equipment

・Vacuum stirrer, exposure equipment, automatic drilling machine - Maintenance, reconstruction, repair, and relocation installation of surface treatment machines

- Parts and consumables for manufacture machines

| Etching Machine | Washing Machine | Roll-Out/Roll-In Machine |

|---|---|---|

|

|

|

| The open/close chamber window vertically separates into two sections that stay fixed in place. The user does not have to worry about where to put the removed lid or getting the floor dirty. | In the washing section, not only does the open/close lid not need to be removed and stowed, but the unit is also constructed for easy access with the open sides and top. | The roll to roll machine is a compact unit that incorporates our in-house know-how, with the specifications in line with the boards that the customer will be treating. |

Sales and Production Bases

We are looking forward to your inquiries on printed circuit board manufacturing equipment (surface treatment machines).

| Toa Electronics Co., Ltd. Tokyo Branch Special Machinery Department |

◎TEL:+81-4-7135-7446 ◎FAX:+81-4-7135-7447 ◎Email:toapcb@toagrp.jp |

|---|